Efficient Use of Spezialbohrgetriebe in Modern Drilling Applications

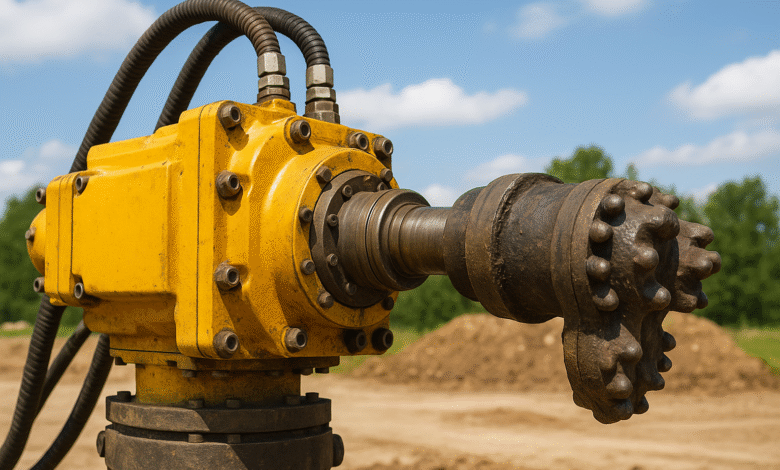

In today’s complex drilling operations, performance, reliability, and precision are more crucial than ever. Whether in construction, geothermal energy extraction, or mining, drilling systems need to handle demanding conditions without compromising on efficiency. One component that makes this possible is the spezialbohrgetriebe, a specialized gearbox tailored specifically for drilling machinery.

This article explores how spezialbohrgetriebe contributes to effective drilling operations, its core advantages, usage across sectors, and the latest technological upgrades. We’ll also cover essential maintenance tips and answer key questions related to its functionality and application.

What is a Spezialbohrgetriebe?

A spezialbohrgetriebe is a high-performance gearbox engineered specifically for use in drilling machines. Unlike standard gearboxes, which are designed for general mechanical applications, this one is customized for high-torque, high-pressure, and precision-heavy environments. These gearboxes are typically found in rotary drills, trenchers, and auger machines, allowing them to handle the unique demands of industrial drilling.

From compact urban construction rigs to large-scale mining drills, spezialbohrgetriebe ensures optimal torque and speed management, even under extreme working conditions. It is a critical mechanical component that supports smooth, safe, and productive drilling operations.

Key Advantages of Spezialbohrgetriebe

1. High Torque Delivery

One of the standout benefits of a spezialbohrgetriebe is its ability to transmit superior levels of torque. Torque plays a vital role in penetrating hard geological layers such as rock or compacted soil. These gearboxes allow drilling machines to generate and sustain the necessary force for deep and challenging excavations.

2. Precision in Speed Control

Different drilling stages require varying levels of speed and force. The spezialbohrgetriebe enables fine adjustments in rotational speed, offering greater control and efficiency. Whether speeding through loose soil or slowly cutting through rock, operators can adjust the drilling speed without mechanical stress or delay.

3. Long-Term Durability

Drilling equipment often works in harsh environments. Be it underground moisture, heat, or abrasive dust particles, these conditions can damage ordinary mechanical components. The spezialbohrgetriebe is constructed with reinforced steel and advanced materials, making it durable and resistant to wear and tear. This translates into fewer breakdowns and lower maintenance costs over time.

Industrial Applications of Spezialbohrgetriebe

Construction Drilling

In construction, especially for laying foundations, accurate and stable drilling is non-negotiable. The spezialbohrgetriebe provides the control and power needed for this task. It helps create deep, precise boreholes for building supports, often in areas where space and maneuverability are limited.

Geothermal Energy Drilling

Geothermal energy systems require drilling deep into the Earth’s crust. These operations often take weeks or months and involve drilling through hard rock formations. With a spezialbohrgetriebe, the rigs used in geothermal projects maintain consistent torque and control, significantly enhancing their operational lifespan.

Mining Operations

Mining drills require high torque and compact drilling mechanisms to bore through rock layers and create access points for resource extraction or explosive charges. A spezialbohrgetriebe ensures these machines operate efficiently while reducing mechanical stress and improving productivity.

Technological Developments in Spezialbohrgetriebe

Smart Monitoring Systems

Recent innovations include digital sensors and real-time monitoring systems. These tools allow technicians to view data such as temperature, torque, and pressure on a dashboard, facilitating predictive maintenance and operational safety. These advancements make the spezialbohrgetriebe not only more effective but smarter and easier to manage.

Advanced Material Coatings

Cutting-edge materials such as ceramic-coated components or carbon composites are increasingly used in spezialbohrgetriebe manufacturing. These materials reduce friction, resist corrosion, and perform better under thermal stress, extending the service life of the equipment.

Maintaining a Spezialbohrgetriebe: Best Practices

Proper maintenance plays a vital role in extending the lifespan of a spezialbohrgetriebe. Here are three maintenance practices to follow:

-

Routine Inspections

Check the gearbox regularly for leaks, noise, or vibration—common signs of internal issues. Early detection helps avoid costly breakdowns. -

Lubrication Management

The gearbox needs proper lubrication to operate efficiently. Replace old oil or grease as per the manufacturer’s guidelines to avoid gear degradation. -

Timely Part Replacements

Gears, seals, and bearings wear down with time. Stock spare parts to ensure quick replacements and reduce unexpected downtimes.

The Future of Spezialbohrgetriebe

Looking ahead, spezialbohrgetriebe are expected to integrate even more seamlessly with AI-driven drilling systems. With the rise of automation and smart construction technologies, future gearboxes will be lighter, more efficient, and capable of auto-adjusting based on terrain and load.

Additionally, sustainable materials and energy-efficient mechanisms will be part of the next generation of spezialbohrgetriebe, aligning with global efforts toward greener industrial operations.

Frequently Asked Questions (FAQs)

Q1: What makes a spezialbohrgetriebe different from a regular gearbox?

A spezialbohrgetriebe is designed specifically for drilling operations. It handles higher torque, offers better speed control, and is made with materials suited to harsh environments.

Q2: Can I retrofit an existing drill with a spezialbohrgetriebe?

Yes, many models are compatible with retrofitting. However, compatibility checks with the machine’s size, torque requirements, and mounting specifications are necessary.

Q3: How often should a spezialbohrgetriebe be serviced?

Service intervals depend on usage and environment, but routine checks every 300–500 hours of operation are commonly recommended.

Q4: Are there different types of spezialbohrgetriebe for different industries?

Yes. While the basic mechanics are similar, there are variations in gear ratios, material durability, and size based on whether it’s used in construction, mining, or geothermal projects.

Q5: Is electronic monitoring a standard feature?

Not always. While newer models often come with sensor-based monitoring, older or budget-friendly versions may lack this feature.

Read also:Geekzilla CES 2023 – A Technological Revolution in Las Vegas